In the heart of our modern world lies an industry as old as civilization itself – mining. From the coal that powers our cities to the rare earth metals in our smartphones, the mining sector forms the bedrock of our global economy. As we stand on the cusp of 2024, this trillion-dollar industry is poised for a remarkable transformation, driven by the fusion of age-old extraction techniques with cutting-edge artificial intelligence.

In 2024, the global mining market is projected to produce an astounding 15,820 billion kilograms of raw materials. This colossal output spans a diverse range of products – from solid coal to liquid petroleum, from metallic ores to natural gas – sourced from over 100 countries across five key sectors. The sheer scale is mind-boggling, with Asia alone contributing 8.91 trillion kilograms in 2023, making it the largest regional player in this global arena.

Yet, as impressive as these numbers are, they also underscore the immense challenges facing the industry. How can we sustain – and even grow – this level of production while simultaneously addressing pressing environmental concerns? How do we balance the voracious global appetite for resources with the imperative of responsible stewardship of our planet?

Recent article by Mckinsey & Company on “How digital and analytics can unlock full potential in steel (Metals and Mining Practice)” indicates a seismic shift in how the metal and mining sector approaches digital transformation and AI adoption. A staggering 78% of companies have already launched digital programs, with 82% considering it a top strategic priority. This widespread adoption underscores the industry’s recognition of AI as a critical driver of both sustainability and profitability. However, the journey is far from complete. While digital leaders are reaping EBITDA improvements of 5-10 $/tonne, an enormous untapped potential of 40-50 $/tonne still exists.

This gap represents not just an opportunity, but an imperative for companies to fully embrace AI-driven solutions. The impact of AI is being felt across the entire value chain, with process digitization, advanced analytics, and robotization/automation emerging as the primary value drivers. For companies still in the “pilot trap” of limited AI implementation, the path forward is clear: strengthen your digital vision, invest heavily in capability building, and secure unwavering commitment from leadership.

As we stand at the cusp of this AI-driven revolution, it’s evident that the metal and mining industry is not just adapting to change – it’s actively shaping a more sustainable and profitable future through the power of artificial intelligence.

The Twin Imperatives: Sustainability and Profitability

In today’s evolving business landscape, sustainability and profitability are no longer mutually exclusive. They are intertwined, driving a new era of growth and innovation in the mining industry. Here’s why these twin imperatives are reshaping the future:

- Environmental Stewardship: The urgency of climate change necessitates a proactive approach to reduce carbon footprints and minimize ecosystem disruption. Mining companies must lead the charge in environmental responsibility, setting new standards for sustainable practices.

- Resource Optimization: As easily accessible deposits dwindle, the focus shifts to efficient extraction and processing. Advanced technologies and AI-driven solutions are essential for maximizing yield from existing resources, ensuring continued profitability even as resources become harder to find.

- Regulatory Compliance: Navigating the maze of increasingly stringent environmental regulations requires innovative strategies. Compliance can no longer be an afterthought; it must be integrated into the core business model to ensure long-term economic viability.

- Stakeholder Expectations: The modern investor, consumer, and community member demands more than just financial performance. They seek companies that embody responsible and sustainable practices. Meeting these expectations is not just about maintaining a positive image—it’s about building trust and securing a loyal, supportive stakeholder base.

AI: The Bedrock of Modern Mining

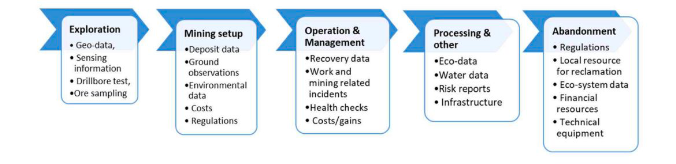

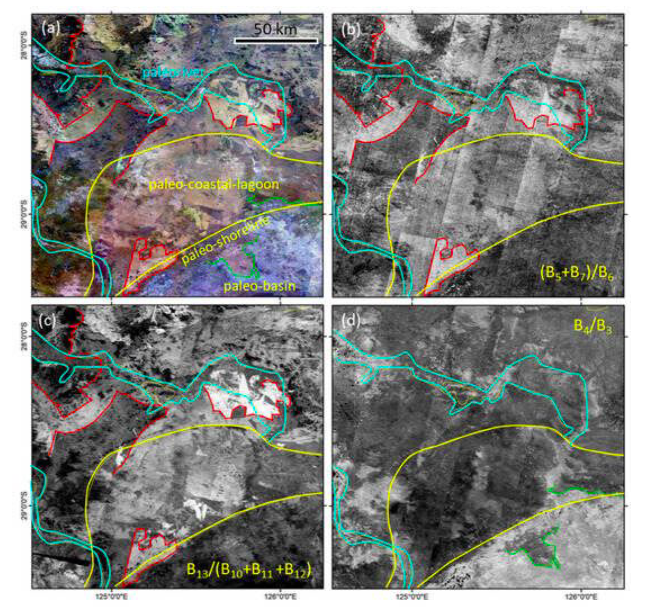

The transformative power of AI in the metal and mining industry extends across the entire lifecycle of resource extraction, from exploration to reclamation. As research indicates, AI applications are proving invaluable at every stage of the mining process.

During exploration, AI algorithms are revolutionizing the way we identify and assess potential mineral deposits, significantly reducing costs and environmental impact. In the exploitation phase, AI is optimizing mine design and production approaches, enhancing efficiency and safety. Perhaps most critically, AI is reshaping mine operations and management practices in ways that directly align with Sustainable Development Goals (SDGs).

For instance, AI-driven predictive maintenance systems are reducing energy consumption and minimizing waste, while advanced analytics are optimizing water usage and reducing environmental footprint. Even in the often-overlooked stages of ore processing and mine closure, AI is playing a crucial role in maximizing resource recovery and ensuring responsible site rehabilitation. By leveraging AI across these diverse areas, the mining industry is not only boosting profitability but also making significant strides towards more sustainable practices.

Artificial intelligence is not just another technological trend; it’s a fundamental shift in how the industry operates. Here’s how AI is addressing the dual challenges of sustainability and profitability:

| Sustainability | Profitability | |

| Predictive Maintenance and Equipment Optimization | Reduced energy consumption, extended equipment lifespan | Reduced downtime, lower capital expenditures, cost savings |

| Autonomous Operations and Safety Enhancement | Reduced emissions, improved safety, optimized fuel consumption | Increased operational efficiency, reduced labor costs, enhanced safety |

| Exploration and Resource Discovery | Minimized environmental impact, precise targeting | Reduced exploration costs, increased accuracy in finding deposits |

| Process Optimization and Waste Reduction | Reduced water and energy consumption, minimized waste | Increased yield, cost savings, improved resource utilization |

| Supply Chain and Logistics Management | Reduced emissions, optimized inventory, minimized waste | Reduced transportation costs, improved efficiency, better demand forecasting |

| Environmental Monitoring and Remediation | Improved air and water quality, enhanced land reclamation, biodiversity conservation | Faster response to environmental issues, optimized restoration efforts |

Image: Exploration and Resource Discovery

Source:MDPI Article

Challenges:

The integration of AI into mining operations presents several challenges that need careful consideration:

- Data Quality and Integration: AI systems rely on high-quality, integrated data from various sources. Many mining operations struggle with siloed and inconsistent data, which can hinder the effectiveness of AI-driven insights and decision-making.

- Workforce Transition: Shifting towards AI-driven operations requires the reskilling and upskilling of the workforce. This transition is complex and sensitive, requiring careful planning and support to ensure employees can adapt to new roles and technologies.

- Initial Investment: Implementing AI solutions often involves significant upfront costs, which can be a barrier for smaller mining companies. Securing investment for AI adoption requires demonstrating long-term benefits and ROI to stakeholders.

- Ethical Considerations: As AI technology advances, ethical concerns such as data privacy, algorithmic bias, and responsible AI use become increasingly important. Mining companies must navigate these issues to maintain trust and transparency in their AI applications.

The Road Ahead: Embracing the AI Revolution

The metal and mining industry stands at a pivotal moment poised for an AI-driven transformation. To fully harness the potential of artificial intelligence, companies should adopt a comprehensive approach:

- Develop a Clear AI Strategy: Begin by aligning AI initiatives with overarching business objectives and sustainability goals. This strategic alignment ensures that AI investments contribute directly to operational efficiency, cost savings, and environmental stewardship.

- Invest in Data Infrastructure: Build robust data collection and management systems that can support AI applications effectively. This includes integrating data from various sources across mining operations to ensure high quality and accessibility for AI-driven insights and decision-making.

- Foster a Culture of Innovation: Cultivate an organizational culture that embraces innovation and AI adoption. Encourage experimentation with new technologies and continuous learning among employees to stay ahead in the rapidly evolving AI landscape.

- Collaborate and Partner: Engage in strategic collaborations with technology providers, research institutions, and even industry competitors. Collaborations can drive collective advancements in AI applications, sharing best practices, and overcoming industry-specific challenges.

- Prioritize Ethical AI: Develop and uphold clear guidelines for the responsible use of AI technologies. Address ethical considerations such as data privacy, algorithmic bias, and transparency in AI decision-making processes. Proactively manage these issues to build trust among stakeholders and ensure ethical compliance in AI deployments.

Real World Use Cases:

Valiance is at the forefront of creating impactful solutions to drive sustainability and profitability in the metals and mining industry. Our cutting-edge technologies are transforming this sector, making operations more efficient and eco-friendly. Here are a few success stories that showcase our expertise:

Reducing Furnace Oil Consumption: A leading aluminum manufacturer implemented AI-driven solutions to reduce furnace oil consumption by optimizing their Twin Chamber Furnace (TCF) and holding furnaces. The results were impressive:

- Oil savings of 5 liters per ton, yielding $100,000 annual cost savings per plant

- 3% reduction in greenhouse gas emissions

- Achieved through AI-optimized Standard Operating Procedures

Prediction of Mushroom Events in Smelting Process: An aluminum smelting company utilized AI to predict and prevent “mushroom” formations during the alumina to molten aluminum conversion process. Benefits included:

- Improved operational efficiency through proactive adjustments

- Potential savings of $240,000 annually with just a 0.1% efficiency improvement

- Enhanced sustainability via better energy use and increased anode recycling

These use cases highlight AI’s versatility in tackling specific technical challenges while delivering significant economic and environmental benefits. They underscore the importance of continued AI adoption and innovation in the metal and mining sector to drive efficiency, reduce costs, and promote sustainable practices.

Key Takeaways:

1. Transformative Potential: AI is revolutionizing the entire mining value chain, from exploration to reclamation, offering unprecedented opportunities to simultaneously boost profitability and enhance sustainability.

2. Data-Driven Optimization: By leveraging advanced analytics and machine learning, AI enables mining companies to make more informed decisions. This data-driven approach leads to substantial improvements in efficiency, resource utilization, and cost reduction, directly impacting the bottom line while minimizing environmental footprint.

3. Enhanced Safety and Environmental Stewardship: AI-powered autonomous operations and real-time monitoring systems not only reduce the risk of accidents but also enable more precise control over environmental impacts.

4. Skill Evolution and Cultural Shift: The successful implementation of AI in mining requires a fundamental shift in workforce skills and organizational culture. This evolution is critical for future-proofing mining operations in an increasingly digital and sustainability-focused world.